When it comes to food, hygiene is extremely important. In a food processing company, the manager is responsible for observing the regulations. The pressure then rests on his shoulders, but how can he really be sure that his employees and operators wash their hands when they are supposed to, and above all properly?

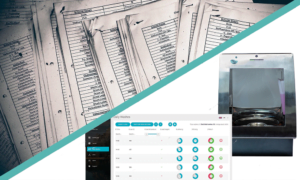

Unfortunately, paper and pencil lists are still too often used in companies, even though more advanced technologies exist that guarantee perfect hand washing.

Unfortunately, paper and pencil lists are still too often used in companies, even though more advanced technologies exist that guarantee perfect hand washing.

All public health authorities are unanimous: hands should be washed with soap and water, rubbed for at least 20 seconds and rinsed thoroughly with warm water (a temperature of 40°C is most frequently recommended). It is also safer not to touch anything after washing your hands until you get to the clean workstation. Turning off the tap or putting one’s name on a list would potentially lead to recontamination of the hands.

This may sound absurd, but it also requires a well-established technique to remove all bacteria and viruses from hands. The supervisor can’t spend his day by the sink to check everything. That’s where technology comes in: the Soapy Hygiene micro-station has built-in sensors that monitor hand movements, and a smart camera that can identify users. It also utilizes AI technology to highlight unclean areas on the skin, and shows how much time needed for an efficient hand wash.

With a simple click, team leaders can know who washed their hands at what time, and which washes were the most effective.

Ask us for a live or virtual demonstration and we will be happy to show you.